Structure of a Zipper Slider_anchor

Structure of a Zipper Slider

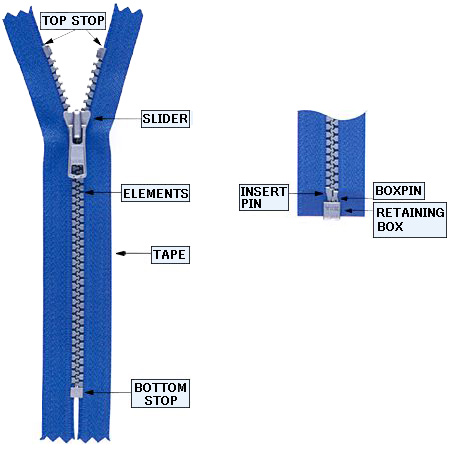

Structure of a Zipper

SLIDER

The slider joins or separates the elements when the zipper is opened or closed. Various types of sliders are available depending on use.

ELEMENTS

The teeth, also known as elements, are the parts on each side of a zipper that mesh, or engage, with each other when passed through the slider. When the left and the right side teeth are engaged they are called chain.

TAPE

The tape is manufactured exclusively for zippers. It is usually made of polyester, but depending on use, synthetic fiber tape, vinyl tape and cotton tape are also available.

Types of Function

How to Measure a Zipper

Standard Slider Functions