Zipper Testing Methods

There are various methods by which to evaluate zipper strength. The basic strength can be determined based on the results of the following inspection methods, from which overall strength appropriate for respective uses can be judged.(Based on JIS-S3015 and ASTM D2061)

※Tensile Testing Machine Conditions ― Tensile Speed: 300 mm/min, Clamp Width: 25 mm

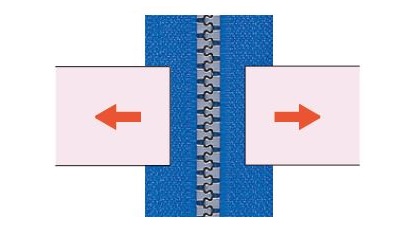

Chain crosswise strength (per 2.5cm)

An engaged zipper chain is pulled crosswise as shown at a constant speed.

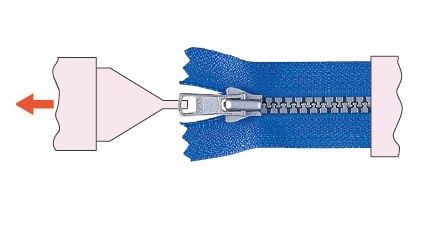

Top stop holding strength

The lower part of an engaged zipper is held securely, then the slider pulled to the top is pulled further up.

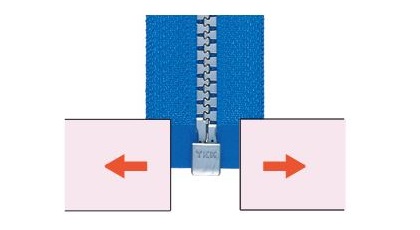

Bottom stop holding strength

The slider is pulled down to the bottom stop, and each side of the chain is pulled outwards in opposite directions.

Separating unit crosswise strength

The slider lock is engaged in the middle of a chain, then each side of the chain is pulled outwards in opposite directions.

Slider lock strength

The slider lock is engaged in the middle of a chain, then each side of the chain is pulled outwards in opposite directions.

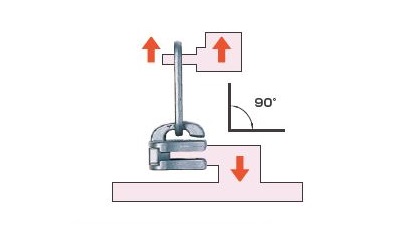

Slider tab pull off strength (90 degree)

Tension force is applied to both the pull-tab and the bottom of the body of an assembled slider.

In addition to the 90°angle shown, a 45°angle is also tested.

(Tensile Testing Machine Speed: 100 mm/min)

YKK® zippers meet UK Standards of Durability and pass the above JIS strength tests.

Plastic Hardware Testing Methods

Buckle tensile strength test

Strap adjuster tensile strength test

Wedge adjuster tensile strength test

D-Ring tensile strength test

Snap hook tensile strength test

Cord stopper tensile strength test

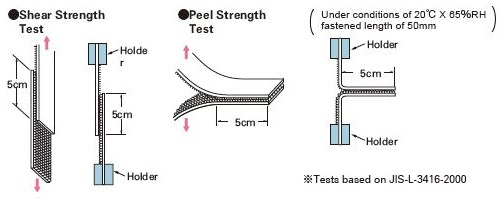

Hook & Loop Testing Methods

Durability Test

Strength of adhesion

Snap and Button Testing Method

.jpg)

Direct Pull Strength (Tack Button)

A force is applied diametrically until the tack button separates from the tack or the fabric is torn. The force at separation is reported as the holding strength.

Peel Off Strength

(Rivet & Burr, Snap, Eyelet & Washer)

A force is applied diametrically until the upper component separates from the

lower component or the fabric is torn. The force at separation is reported as the holding strength.

.jpg)

Direct Pull Strength (SNAPET®)

A force is applied diametrically until the prong ring separates from the socket or stud or the fabric is torn. The force at separation is reported as the holding strength.

(Quote: ASTM D7142-05)

.jpg)

Lateral Strength

(Hook & Eye)

A force is applied diametrically until the hook or eye separates from the plate or the fabric is torn. The force at separation is reported as the holding strength.

.jpg)

Slippage Strength (SOFIX®)

A force is applied continuously until the snap part (injected) is broken.

.jpg)

Lateral Holding Strength (SOFIX®)

A force is applied continuously until the socket and stud separate from each other.

The force at unsnapping is reported as the holding strength.