Resource Conservation2018.12.27

What is the fashion industry doing to reduce water consumption?

Episode 3

Fashion industry and water resources

There has been extensive media coverage on the effect the fashion industry has on water resources. Dyeing has a particularly large impact on the environment. Using conventional technology, a massive amount of water is required not only in the actual dyeing process but also for bleaching before and washing after dyeing, as well in finishing processes such as ageing.

Today, a total of 2.8 million tons of textiles are dyed each year around the world, requiring the use of about 5 trillion liters of water. This is the equivalent of 2 million Olympic-size (50-meter) swimming pools' worth of water*1. (This is the equivalent of 47-days' worth of fresh water used in the United States.) In other words, an enormous amount of water is consumed. What is more, in developing countries, textile dyeing effluents are sometimes disposed of without undergoing any treatment. There are reports that this causes serious water pollution.

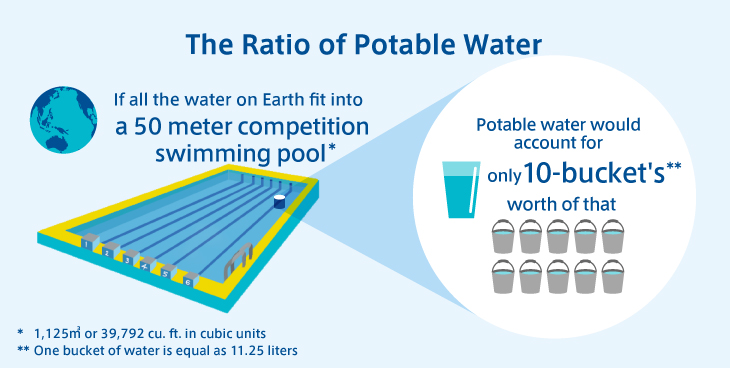

With the increase in the global population, overall water use—including water used by other industries, such as agriculture, in addition to fashion—is expected to increase by more than 40% by 2030*2. Competition over water will become even greater. There is 1.38 billion cubic kilometers of water on Earth, the majority of which is seawater. Fresh water, which can be used immediately, accounts for only 0.01% of all water on Earth. Imagine all of the Earth's water fitting into an Olympic-size swimming pool. Fresh water would account for only about 10-buckets worth of that. There are great expectations being placed on the fashion industry to play a big role in making this valuable resource sustainable.

Efforts of the fashion industry to reduce water usage

To address this problem, technology is being developed to suppress the amount of water used during dyeing and finishing processes. The innovative technology contained in ColorZen® made it a winner at Copenhagen Fashion Summit 2018. ColorZen® allows cotton to absorb dyes more easily through pretreatment. It has succeeded in reducing the amount of water required when dyeing cotton by 90%*3.

A new technology has also been developed for the denim ageing process, which is also known to pose a heavy burden on the environment. Jeanologia™'s finishing technology utilizes laser, ozone and nanobubbles to achieve processing that reduces the amount of water used to a minimum. In fact, Jeanologia™ has announced that its latest technology enables a single garment to be finished with just one glass of water.*4

The fashion industry is using more than technology to address the issue of water. The ZDHC*5 is an industry group in which over 100 fashion brands and organizations (as of 2018) participate. In addition to working toward the major goal of eliminating toxic releases through its Roadmap to Zero Programme, the ZDHC has also announced unified restriction guidelines*6 to decrease the impact of the industry on water resources. While there were different environmental standards that had been established to address the issue of decreasing the load on water resources, they have been unified through the ZDHC guidelines, making it easier for more companies to engage in related efforts.

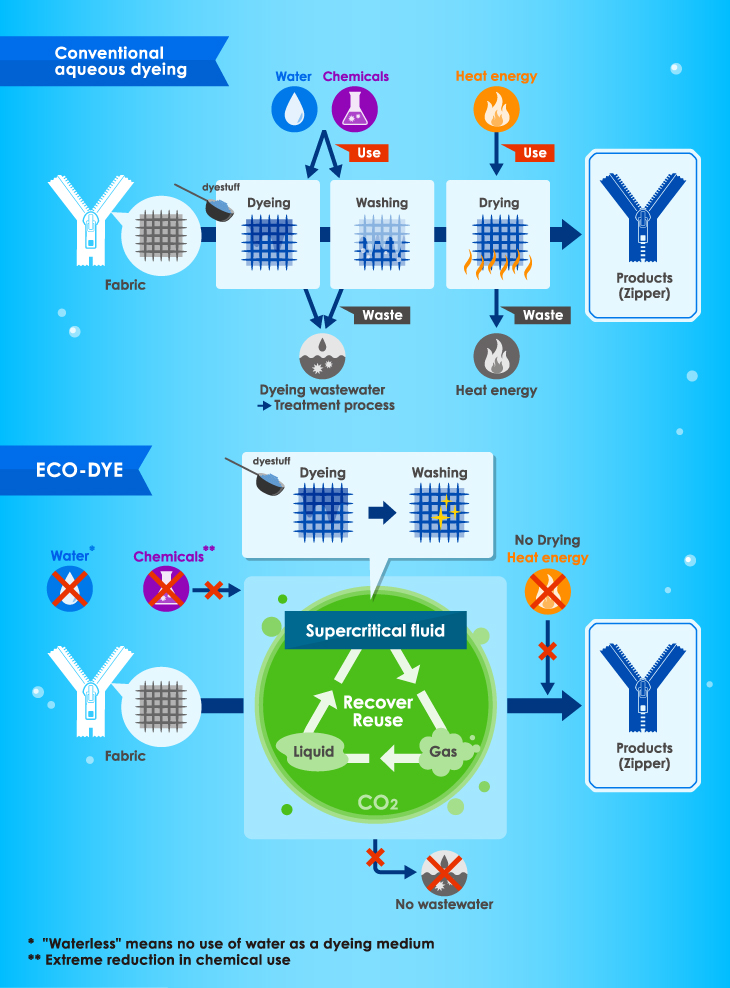

YKK technologies to reduce water usage

YKK continues to tackle the challenge of reducing the impact of the production of its products on water resources. One way YKK is meeting this challenge is through its dyeing technology known as ECO-DYE®, a revolutionary dyeing technology that uses almost no water. Carbon dioxide is used instead of water, and a supercritical fluid, which has the properties of both liquid and gas, is generated by applying heat and pressure to the carbon dioxide. Since matter changes through the application of heat and pressure, zipper tapes and elements can be dyed using almost no water. This has resulted in a reduction of between 50% and 90% in the amount of water used during the overall production process of zippers.

YKK also produces metal products that use less water during the manufacturing process.

As in the case of dyeing, water is used during the plating process of metal buttons and rivets for jeans and other apparel. YKK has developed Environmental Friendly Finish (Snap Fastener Finishing Technology), an original technology which enables a finish that makes the most of the color of the metal material. Environmental Friendly Finish (Snap Fastener Finishing Technology) has reduced the amount of water used when manufacturing such items by an average of 75%. YKK has also succeeded in reducing the amount of electrical power consumption used in metal plating by an average of 90%. The detergent and chemicals used in the processes before finishing have also been reduced. Other efforts include the use of crushed walnut shell media during the filtering of wastewater as well as in devices used for washing in order to decrease waste as much as possible.

YKK will continue to decrease its impact on the environment, especially regarding water consumption. We will also continue our collaboration with industry groups, other companies, and the local and national governments of other countries and regions to help the overall fashion industry resolve environmental challenges.

"ECO-DYE®" is registered trademark of YKK CORPORATION in Japan and other countries/regions

"ColorZen®" is a registered trademark of ColorZen Inc.

"Jeanologia™" is a trademark of Jeanologia S.L.

Related Links

Related Episodes

-

- SUSTAINABILITY2018.09.01

- YKK produces 3 million kilometers worth of zippers every year – enough to circle the globe over 80 times.

Zippers have become essential to daily life

Today, zippers are used in a vast array of products, ...

-

- Emission Reduction2018.10.19

- It is often the small, ingenious efforts that change the world

One characteristic of the fashion industry is its complex supply chain. According to an OECD report, ...

-

- Brand Protection2019.01.31

- YKK promoted brand protection and partnership through B.P.P. initiative

Counterfeit goods cost economies US$461 billion....

-

- Resource Recycling2019.3.31

- Plastic Bottles and Recycling in Fashion

Plastic bottles are convenient containers that ....

-

- Emission Reduction2019.5.20

- Carbon-neutral initiatives by YKK and the global fashion industry

In 2018, it seemed that we were feeling the effects ....

-

- Decent Work2019.7.31

- Gender Issues in the Fashion Industry: How YKK is Promoting Women's Empowerment

Issues Facing Women in the Fashion Industry ....

-

- Reduced inequality2019.11.29

- YKK's Fair Fashion and Partnership Initiative

Toward a Society that Protects the Rights and Dignity of All People ....

-

- Vocational Education2020.2.28

- YKK Initiatives for Students Seeking a Career in the Fashion Industry

Insufficient skills and talent to respond to changing times ....

-

- Working Environment2020.3.13

- YKK Builds Safe and Healthy Working Environments

From achieving employee happiness to achieving a sustainable society ....

-

- Resource Recycling2020.4.10

- The Fashion Industry Responds to the Ocean Plastic Pollution Crisis

Ocean plastic causes environmental pollution, damages ecosystems ....

-

- Hazardous Substance Management2020.6.25

- The Problem of Hazardous Substances in the Fashion Industry and YKK Initiatives

Environmental pollution due to chemical substances ....

-

- Emission Reduction2020.10.8

- Fashion industry and YKK initiatives to reduce greenhouse gases

Increasing greenhouse gases and their impact on the world ....

-

- Reduced Inequalities2021.3.26

- Diversity, Equity, and Inclusion

Growing Focus on Diversity, Equity, and Inclusion Around the World ....

Sources:

*1

https://glasaaward.org/wp-content/uploads/2015/05/GLASA_2015_StateofApparelSector_SpecialReport_Water_150624.pdf

https://water.usgs.gov/watuse/wuto.html

*2

https://makewealthhistory.org/2014/05/30/the-water-food-energy-nexus/

*3

https://www.innovationintextiles.com/colorzen-wins-innovation-competition/

*4

https://fashionunited.uk/news/fashion/jeanologia-on-how-to-make-the-denim-industry-more-sustainable/2017102726481

*5

https://www.roadmaptozero.com/about/

*6

https://www.roadmaptozero.com/fileadmin/content_2016/Files_2016/ZDHC_Wastewater_Guidelines.pdf

https://www.aquas5.jp/100/post.php