The Problem of Hazardous Substances in the Fashion Industry

Environmental pollution due to chemical substances is seen as an issue in the fashion industry. There are concerns about manufacturing processes such as dyeing and waterproofing, as well as pesticides used in cultivating cotton raw material, which can pollute water systems and the soil and adversely impact biodiversity. It has also been pointed out that this environmental pollution can circle around to impact the health of people. When polluted water is used for household drinking water, or when crops or seafood are harvested from contaminated water systems or soil, the substances can be directly ingested by people and adversely impact their health. People working in locations where these chemicals are used also face a health threat due to direct or indirect contact with the chemicals. Furthermore, prolonged skin contact with clothing, shoes, and bags containing chemical substances may lead to illnesses such as allergies and cancer*1.

In responding to the problem of hazardous substances, the fashion industry must tackle the issue in terms of both manufacturing processes and product materials.

1) Issues in Manufacturing Processes

In recent years, attention has been drawn to the environmental damage caused by manufacturing processes and the health risks for people engaged in those processes. Leading the response is the international NGO Greenpeace. In July 2011, the organization launched its Detox Campaign (2011) with the goal of fighting water pollution caused by chemicals*2. The campaign identified 11 substances as priorities for eradication and sought a response from fashion brands. Major brands responded with a series of "Detox Declarations."

The goal was not only to eliminate residual chemicals in clothing, but also to stop the discharge of hazardous chemicals in all manufacturing processes. "All manufacturing processes" refers to the entire global supply chain. In 2018, Greenpeace audited 80 brands that were responsible for 15% of the world's clothing production and released a report showing the progress that brands have made in eliminating the use and discharge of hazardous chemicals*3.

2) Issues in Product Materials

Chemicals that have been identified as problematic in the fashion industry include PFCs, heavy metals (lead, cadmium, chromium, etc.), phthalic acid, and organotins. Due to their abundance and low cost, there are more than 3,000 kinds of azo dyes used in the world*4. Some of these azo dyes may produce carcinogenic-specific aromatic amines, which may cause reproductive or developmental failures if they accumulate inside organisms over a long period of time.

Actions to Reduce Hazardous Substances

In February 2006, the United Nations Environmental Programme (UNEP) approved the “Strategic Approach to International Chemical Management,” a program that was put together by the International Conference on Chemicals Management (ICCM). This helped spread awareness around the world of the importance of chemical management, especially the introduction of chemicals in manufacturing processes*5.

In 2009, as a preliminary to the aforementioned Detox Campaign (2011), Greenpeace conducted surveys of factory wastewater in China's Pearl River Delta, one of the areas of China with a particularly large concentration of garment manufacturers. The organization announced that a large number of hazardous chemicals were detected and that the originating plants shipped fabrics to world-famous brands. The survey results showed that it was essential to undertake initiatives across the entire supply chain of the manufacturing process in order to eliminate hazardous substances.

Currently, many brands are tackling the issue not just in terms of the final product, but across the entire manufacturing process supply chain. They are helped by industry activities such as the ZDHC*6 industry organization and the OEKO-TEX® community*7, which is composed of research and testing institutions. The ZDHC (Zero Discharge of Hazardous Chemicals) group includes major fashion industry companies. It helps to accelerate company initiatives by providing safety management programs, restricted substances guidelines, and the information aggregator ZDHC GATEWAY platform. Meanwhile, the OEKO-TEX® community (consisting of 24 national and regional testing and research institutes around the world) administers the international safety standard OEKO-TEX® certification for textile products. It supports the safety management efforts of manufacturers by conducting safety standards-based audits of products submitted for certification by those companies.

Image from the website of ZDHC (Zero Discharge of Hazardous Chemicals).

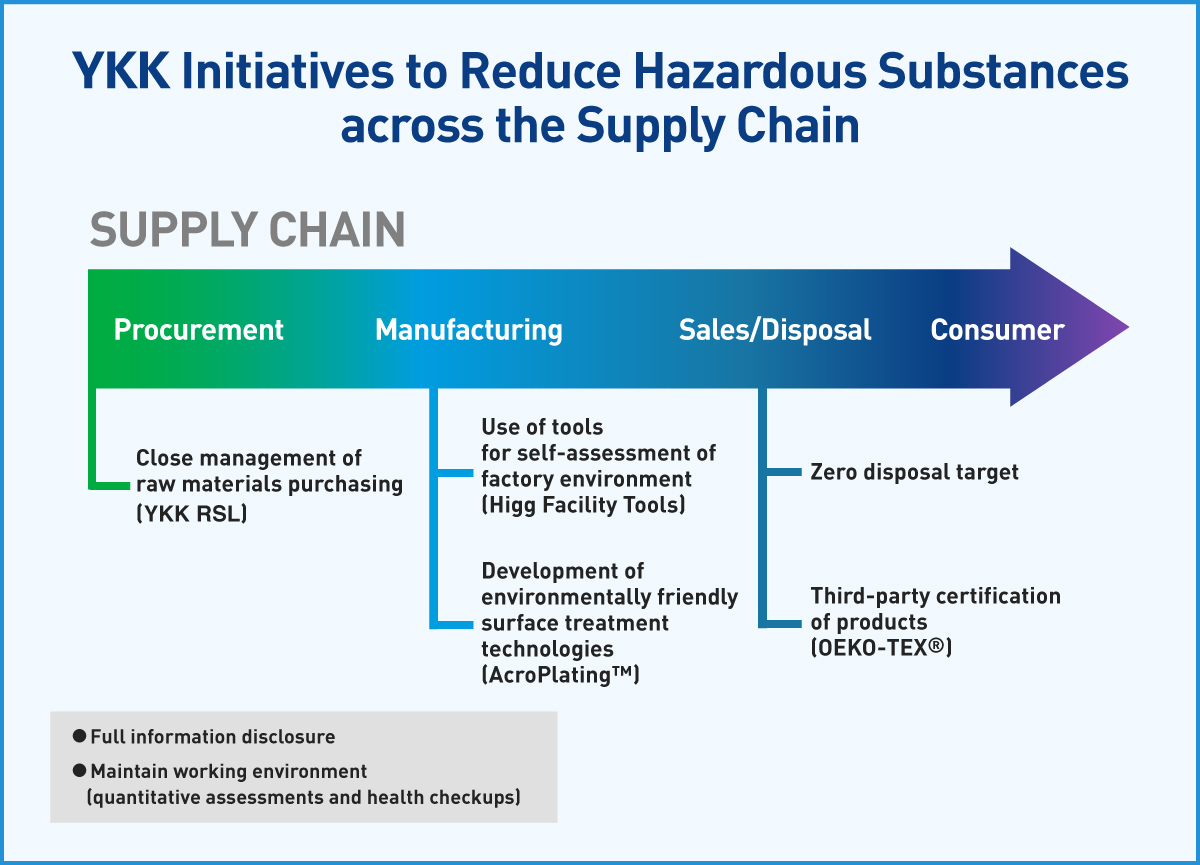

YKK Initiatives to Reduce Hazardous Substances

At YKK, we maintain our own list of restricted substances (YKK RSL) and work to reduce hazardous substances in all processes, from raw material procurement to manufacturing and disposal. For certain items we apply for third-party certification, such as OEKO-TEX® certification and the even stricter bluesign®*8 certification. These provide third-party confirmation of our hazardous substances management efforts.

Structure of YKK's Management System

In procurement, we maintain our own Restricted Substances List (YKK RSL)*9 based on multiple industry standards and focus on only purchasing raw materials that meet the standards. For example, we develop materials with reduced amounts of PFCs (perfluorinated compounds), which are widely used in the fashion industry for waterproofing.

We have set targets of zero discharges by 2020 of surfactants, halogenated solvents, organotin compounds, PFCs, phthalic acid ester, heavy metals, azo dyes, and PAH*10 and are undertaking initiatives to achieve these targets*9. In addition, we are developing environmentally friendly surface treatment technologies (which reduce water and power consumption, reduce emissions, and do not use hazardous plating chemicals), while pursuing a range of other initiatives, including working environment maintenance (safety management and health checkups). In these activities, we work to ensure transparency by using Higg Facility Tools*11, which are environmental self-assessment tools used across the industry.

YKK Works With the Community

At YKK, we are facing the problem of hazardous substances in the fashion industry head-on. As a player in the industry we take into account a range of perspectives to enact measures and reduce hazardous substances. In order to maintain a clean global environment for the next generation, we must not only make technology sustainable, but also our manufacturing systems and management methods. In this way, YKK is doing its utmost to manage manufacturing in a way that takes into consideration the environment, communities, customers, and employees.